Introducing the Lucent360™ Advanced Photoreactor

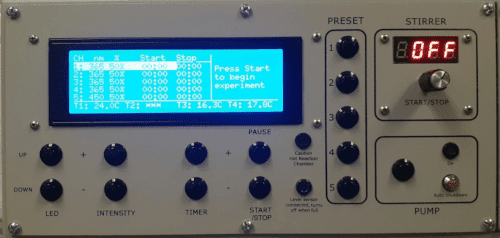

The Lucent360™ Advanced Photoreactor enables parallel (screen), batch and flow with wavelength, light intensity and temperature control in one device.

- Multiple vial formats and configurations (from 0.3 ml to 700 ml)

- Temperature controlled (0°C to 80°C) with thermostatic fluid

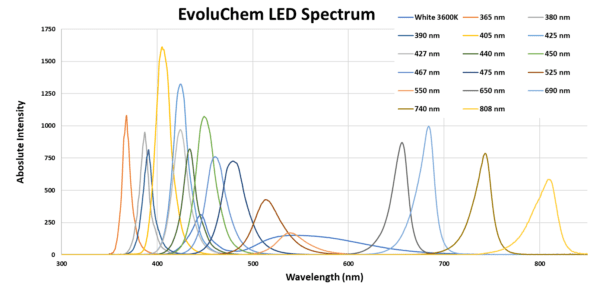

- Interchangeable LED light modules (254 nm through 808 nm)

- Screen up to 4 wavelengths and/or light intensities simultaneously

- Heavy duty magnetic stirring

- Pre-set your favorite experiments for quick repeatability

Industry Leading Photoreactor Design

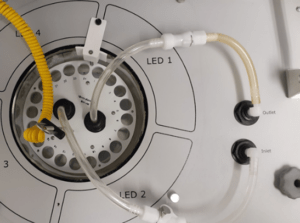

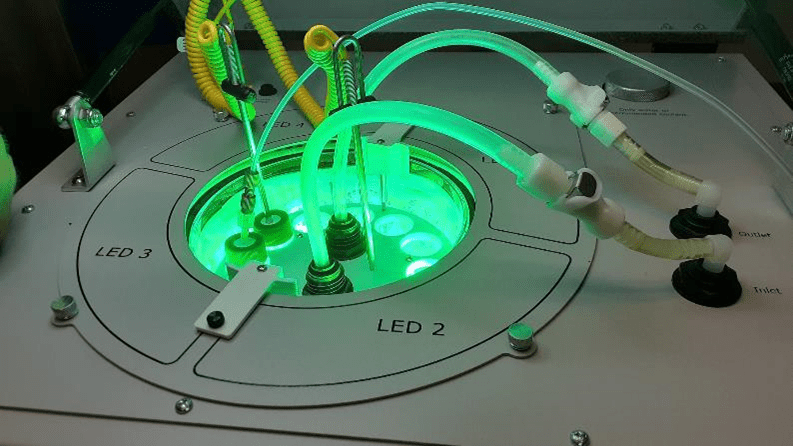

The Lucent360™ Advanced Photoreactor is the most comprehensive photoreactor on the market. It’s patented design provides the most flexibility for parallel, large batch and flow photochemistry. Reaction vials are immerged in a thermostatic bath controlled by an external heater/ chiller unit, enabling temperature controlled experiment conditions. Light irradiation is provided by custom, interchangeable light modules that surround the reaction chamber. The reaction chamber itself is comprised of 2 glass walls (Dewar) that thermally insulate light sources from the reaction vial bath.

Designed for maximum control of samples irradiation

Unparalleled Control of Light Wavelengths and Intensities

The Lucent360™ includes 5 light modules that can be controlled independently. Each module has multiple LEDs that operate at a specific wavelength.

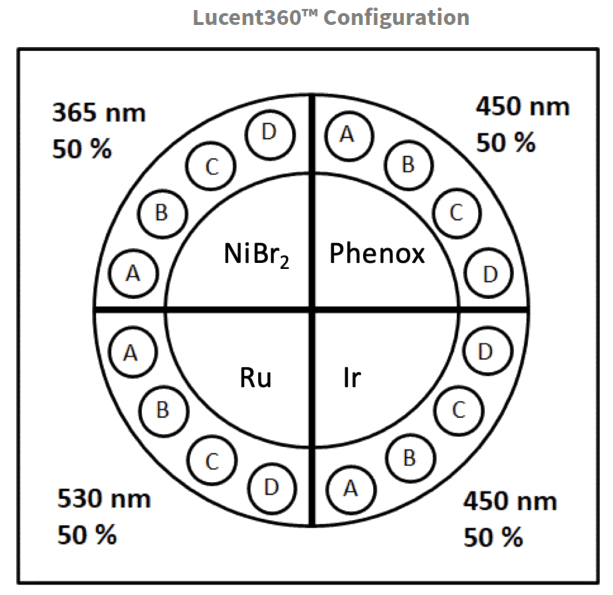

The light modules are interchangeable and, when using a light screening holder in the reaction chamber, enables conditions that can screen multiple wavelengths or light intensities simultaneously.

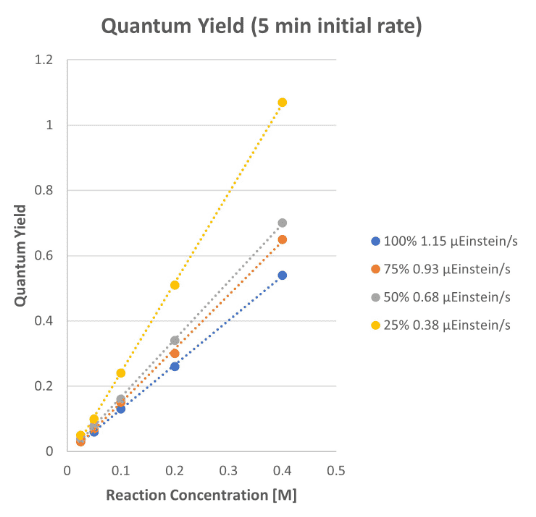

Light Irradiance Screening

Each light module is set at different intensity to investigate quantum yield of your reactions.

Module 1: 100% Module 2: 75%

Module 3: 50% Module 4: 25%

Wavelength Screening

Each light can be set with a different wavelengths to study several catalytic systems simultaneously.

Module 1: 365 nm Module 2: 450 nm

Module 3: 450 nm Module 4: 525 nm

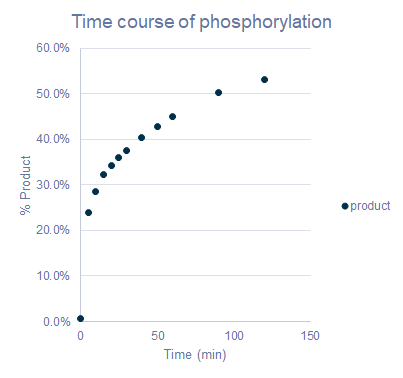

Timecourse Experiment

Each light module can be set with different irradiation time in parallel or in sequence.

Module 1: 30 min Module 2: 60 min

Module 3: 120 min Module 4: 240 nm

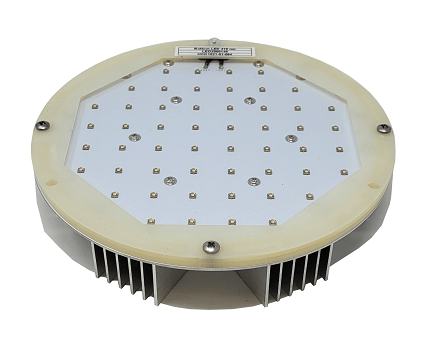

Interchangeable Light Modules

Side Light Module

Bottom Light Module

Easy Access to Light Modules

Wavelengths Available:

254 nm, 275 nm, 300 nm, 310 nm, 340 nm, 365 nm, 380 nm, 390 nm, 405 nm, 425 nm, 427 nm, 440 nm, 450 nm, 475 nm, 505 nm, 525 nm, 595 nm, 650 nm, 740 nm and 808 nm.

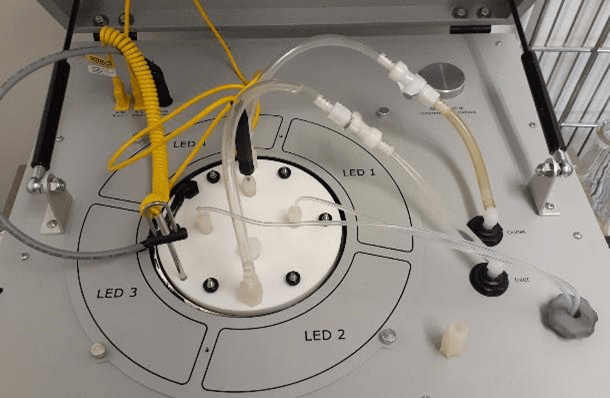

Multiple Reactor Vessels Enable Parallel, Batch, Flow Reaction and Light Screening

Compound Library

Batch Reaction

Flow Reactor

Light Module Screening

Testimonials in Literature

Scale-Up Capability: up to 700 ml

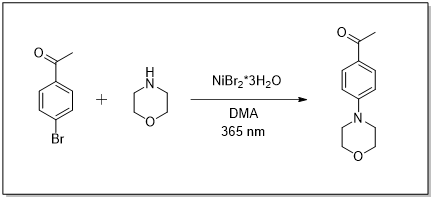

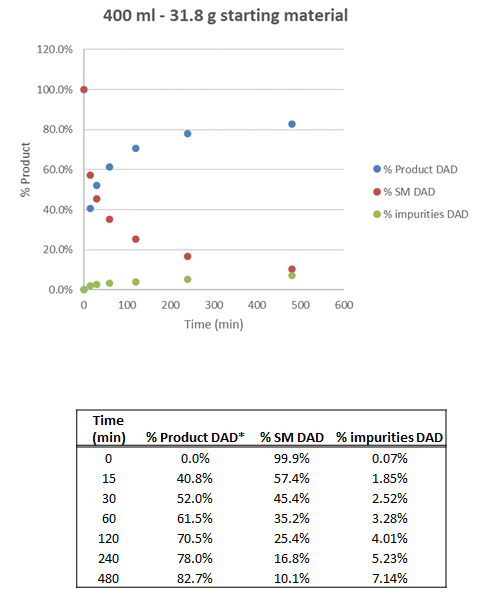

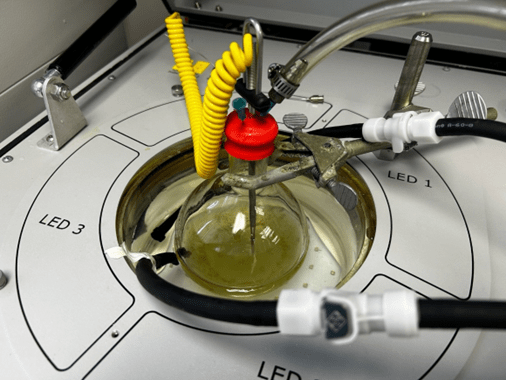

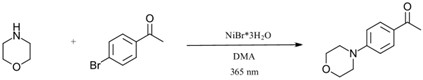

Scale up: 400 ml scale up (0.16 mol) reaction in Lucent 360 with 365 nm light (5 modules @ 50 %) –Temperature set at 20 °C

Experiment: Reaction was performed in Lucent360 Advanced Photoreactor with 700 ml reactor chamber equipped with 5 -365 nm light modules (4 side LEDs and 1 bottom LED) set at 50% light intensity with external chiller set at 20 °C. To the reaction chamber was added 31.8 mg 4-bromoacetophenone (0.16 mol), 48.7 ml morpholine (0.56 mol, 3.5 equiv.) and 2.18 g NiBr2·3H2O (8 mmol, 5 mol%) and 400 mL dimethylacetamide (final concentration 0.4 M). The reaction chamber was sparged with N2 prior to starting the reaction. Upon turning on the LEDs, the temperature of the reaction as monitored by a temperature probe in the reaction mixture initially increased to 29 °C before stabilizing at 27 °C during the length of the reaction. The LEDs were turned off momentarily at regular intervals and aliquots of the reaction were removed and diluted in DMSO for analysis by LC-MS. After 4 hours, 77.9% conversion to product was observed by DAD. Following an additional 4 hours of reaction time (8 total), conversion increased to 82.7% by DAD (est. 27.0 g product) with 10.1% 4-bromoacetophenone remaining by DAD.

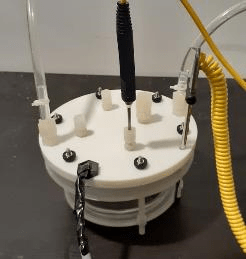

Round bottom flask adaptor

Experimental Description: Reaction performed at 10 g scale of 4-bromoacetophenone in 500 ml round bottom flask inside Lucent360 attached vial round bottom adapter. Reaction was performed at 0.2 M in DMA (250 ml solvent) with stirring via Teflon stir bar under a constant stream of nitrogen provided via nitrogen line on side entrance hole of the instrument. The reaction was cooled via water bath with external chiller with temperature set at 25 C. Temperature inside the flask was monitored via temperature probe attached to T1 on instrument and remained constant through the reaction (~27-28 °C). Water bath temperature is monitored via internal temperature probes (~26 °C). The flask was illuminated at 365 nm with 4 side light modules and 1 bottom light module operating at 50% light intensity. Aliquots of the reaction were removed and monitored by LC-UV-MS. Product conversion was determined by integration of DAD signal and the reaction was stopped after 16 hours.

Temperature Controlled Environment (0° to 80° C)

The Lucent360™ advanced photoreactor includes standard circulation ports on all of its vial holders as well as an internal water pump and high performance heat exchanger.

Connecting the Lucent360™ to a standard heater/chiller unit enables accurate temperature controlled reaction conditions (0° to 80° C) that are insulated from the heat of light modules.

A temperature probe (included) can also connect to each of the Lucent360™ vial holders, allowing for precise measurements. Fill and flow rate is controlled by the manual valves accessed on the front panel.